Innovative Metal Processing: Why Laser Cutting Leads the Way

In the world of metal fabrication, innovation continues to shape how materials are processed, assembled, and utilized. Among the many advancements in this field, laser cutting has emerged as a groundbreaking technique that has revolutionized metal processing. Its precision, efficiency, and versatility make it the go-to solution for industries ranging from automotive to aerospace and beyond.

What is Laser Cutting?

Laser cutting is a manufacturing process that uses a high-powered laser beam to cut through various materials, including metals like steel, aluminum, and titanium. By focusing the laser’s energy into a narrow beam, the material is either melted, burned, or vaporized, creating clean and precise cuts. Coupled with advanced software, laser cutting machines can produce intricate designs and patterns with minimal human intervention.

The Advantages of Laser Cutting

- Unmatched Precision One of the primary reasons laser cutting stands out is its incredible precision. The focused laser beam allows for highly accurate cuts, even on complex designs. This level of precision reduces the need for additional finishing work, saving both time and resources.

- Efficiency and Speed Laser cutting significantly reduces production times compared to traditional methods. High cutting speeds combined with automated systems ensure that large volumes of work can be completed quickly without compromising quality. This makes it an ideal choice for industries requiring fast turnaround times.

- Versatility Laser cutting can be used on a wide range of metals, including carbon steel, stainless steel, and non-ferrous materials. Its ability to handle various thicknesses and shapes means it’s adaptable to diverse projects, from industrial components to decorative designs.

- Cost-Effectiveness While the initial investment in laser cutting equipment can be high, the long-term benefits outweigh the costs. Its efficiency minimizes material waste, and the lack of wear and tear on cutting tools reduces maintenance expenses. Over time, this translates to significant savings.

- Enhanced Design Capabilities The integration of computer-aided design (CAD) software with laser cutting machines allows for intricate and complex designs to be executed flawlessly. This capability is particularly valuable in industries like jewelry, electronics, and custom manufacturing.

Applications of Laser Cutting in Metal Processing

The versatility of laser cutting has led to its adoption across numerous industries:

- Automotive: Used for creating precise components such as gears, brackets, and panels.

- Aerospace: Essential for cutting lightweight yet strong materials like titanium and aluminum.

- Construction: Ideal for producing structural elements with complex shapes and patterns.

- Electronics: Enables the creation of small, precise parts for electronic devices.

- Art and Design: Provides the ability to craft intricate metal sculptures and decorative pieces.

Why Laser Cutting is the Future

As industries continue to demand higher efficiency and precision, laser cutting remains at the forefront of metal processing technologies. Innovations such as fiber lasers and advancements in automation are further enhancing its capabilities. Fiber lasers, for instance, offer even greater speed and energy efficiency compared to traditional CO2 lasers, making them an attractive option for forward-thinking manufacturers.

Additionally, the integration of artificial intelligence and machine learning into laser metal cutting systems promises to make these machines smarter and more adaptive. With predictive maintenance, improved accuracy, and reduced downtime, laser cutting is set to remain a cornerstone of modern fabrication.

Conclusion

Laser cutting has transformed metal processing by delivering unmatched precision, speed, and versatility. Its ability to adapt to various industries and applications makes it an indispensable tool in modern manufacturing. As technology continues to evolve, laser cutting is poised to lead the way in innovative metal processing, driving efficiency and creativity to new heights.

-

Education & Science4 years ago

Education & Science4 years agoAPES Unit 4 Study Guide: Essential Topics and Tips for Exam Success

-

Real Estate & Travel4 years ago

Real Estate & Travel4 years agoSan Pancho Mexico Real Estate Opportunities For Your Dream Home

-

Local Listings & Activities6 years ago

Local Listings & Activities6 years agoWe Rock the Spectrum Bradenton Inclusive Play and Sensory Gym for All Kids

-

Education & Security4 years ago

Education & Security4 years agoInsider Threat Indicators Description and Detection Guide

-

Relationships & Quotes6 years ago

Relationships & Quotes6 years agoAppreciation Deep Mother Quotes in Spanish

-

Music & Concerts2 years ago

Music & Concerts2 years agoDave Matthews Band Virginia Beach Concert Guide

-

News & Obituaries1 year ago

News & Obituaries1 year agoRobert F Kennedy Jr: Net Worth, Career and Legacy

-

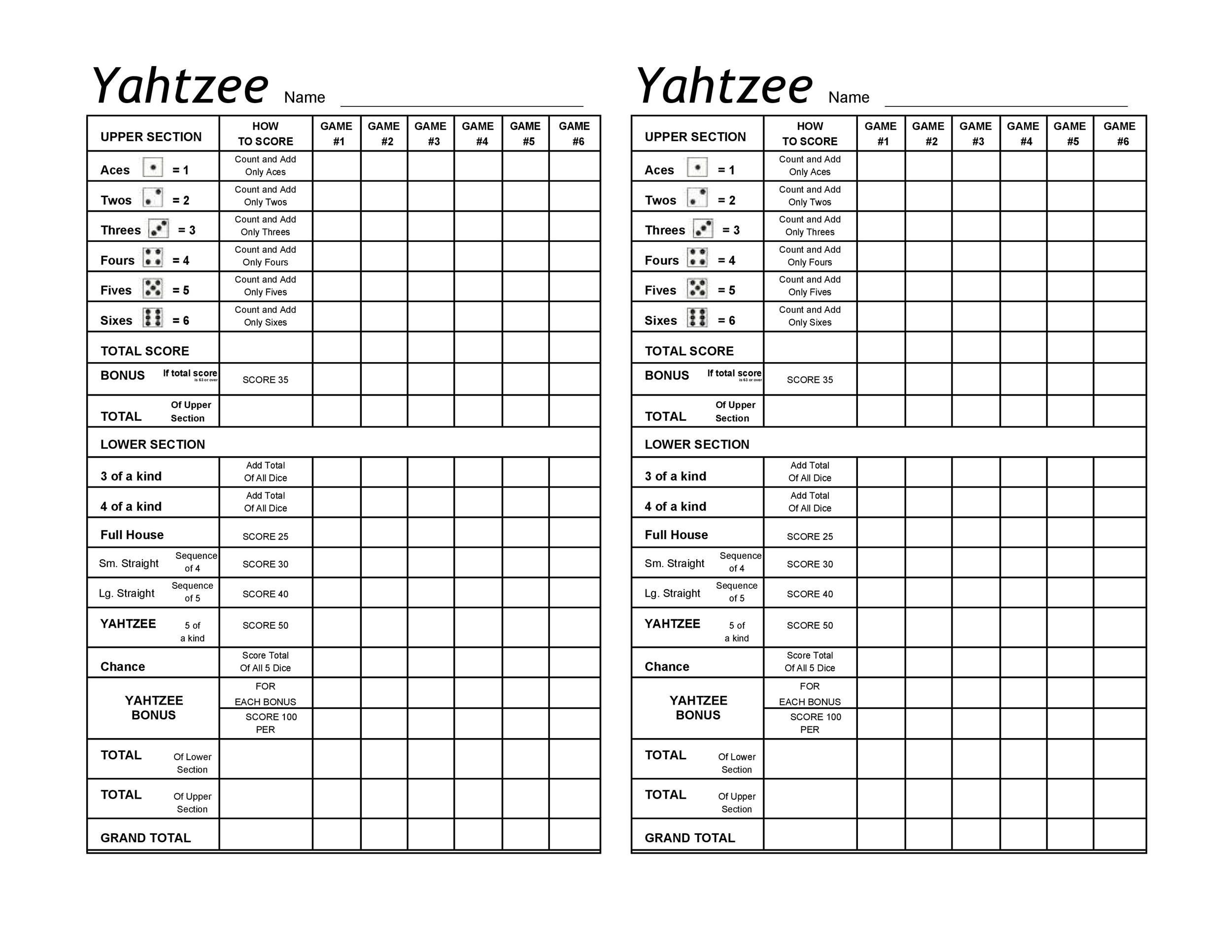

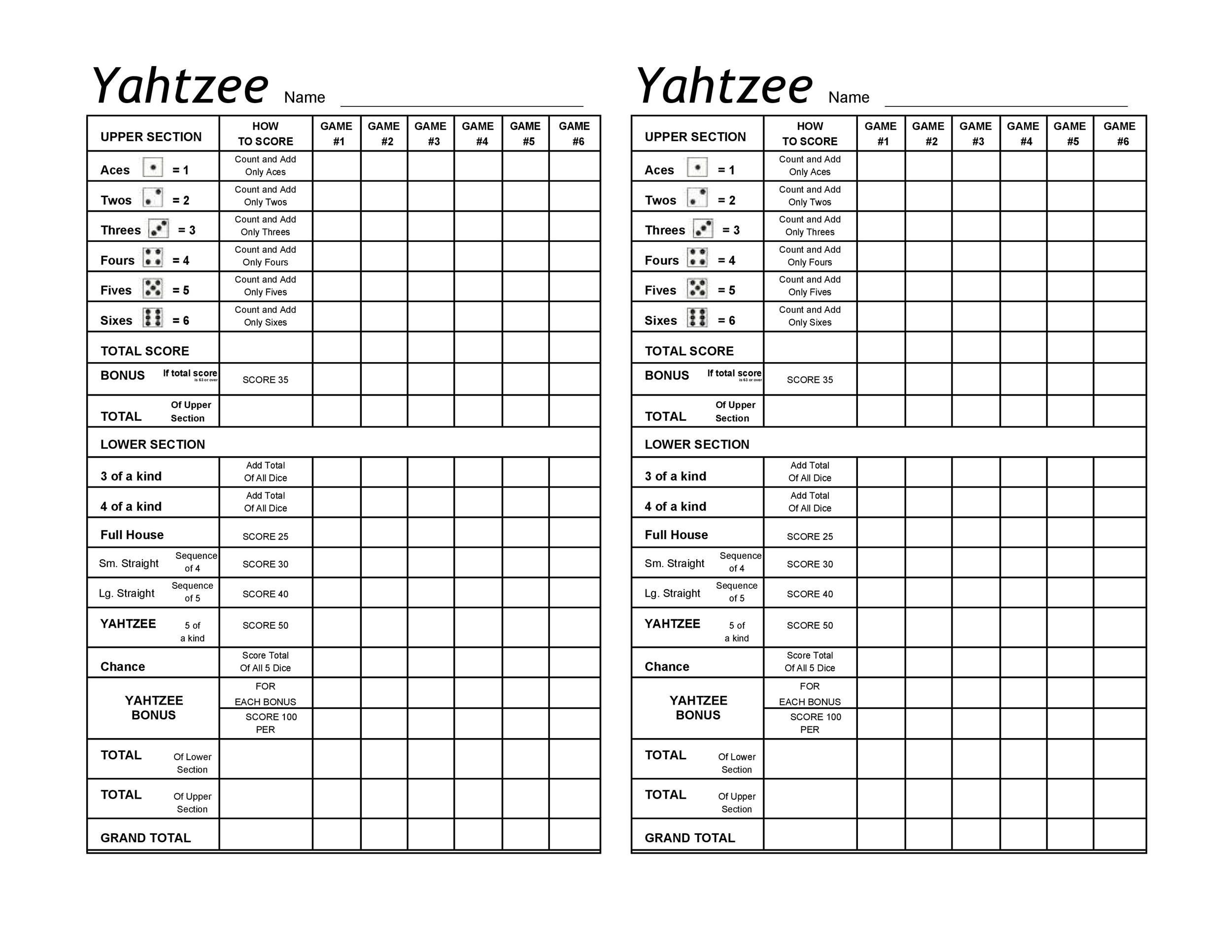

Games & Printables5 years ago

Games & Printables5 years agoFree Printable Triple Yahtzee Score Sheets PDF for Easy Game Tracking